Responsive Kinetic Paneling

Concept, Engineering, Prototype, Physical Computing

The Challenge

To research and develop a dynamic architectural “skin” with panels that can adapt to environmental conditions. The goal was to create a functional system that could solve real-world problems, such as providing natural ventilation for an enclosed space by intelligently venting excess heat and improving air quality. A possible future application is a structure with an enclosed firepit that is smart enough to automatically vent dangerous carbon monoxide and excess heat.

My Solution & Approach

This project chronicles the iterative journey of bringing an abstract concept for a responsive facade to life through hands-on prototyping. Inspired by the principles of Kinetic Architecture and biomimicry, I am developing a modular, sensor-driven paneling system.

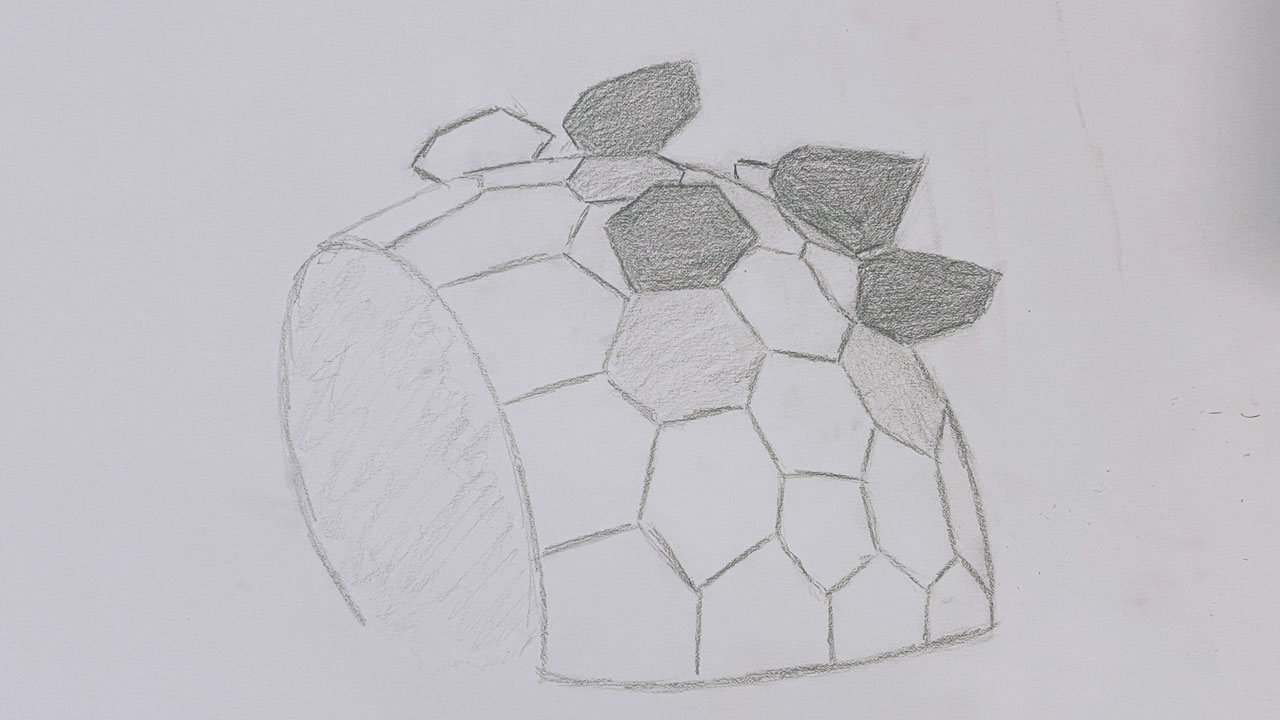

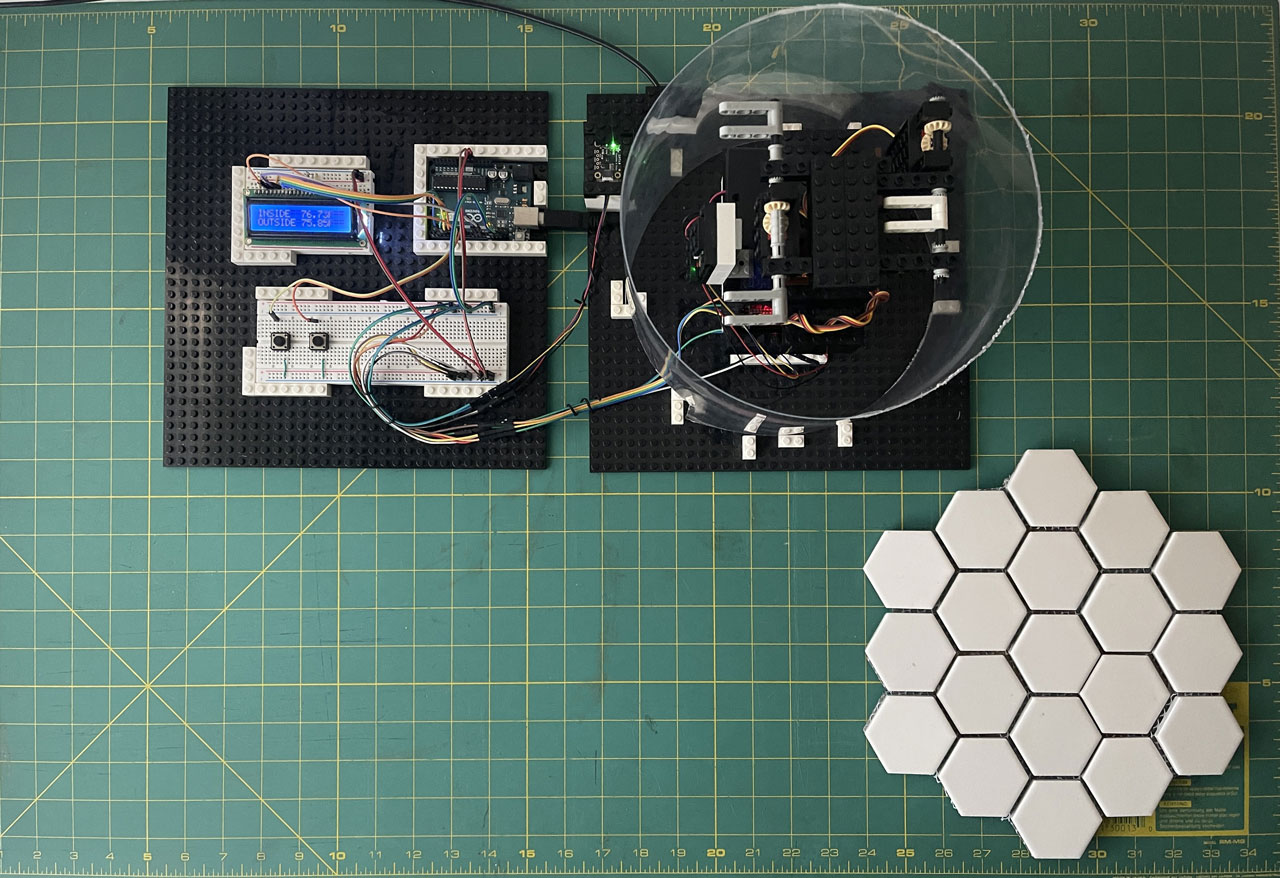

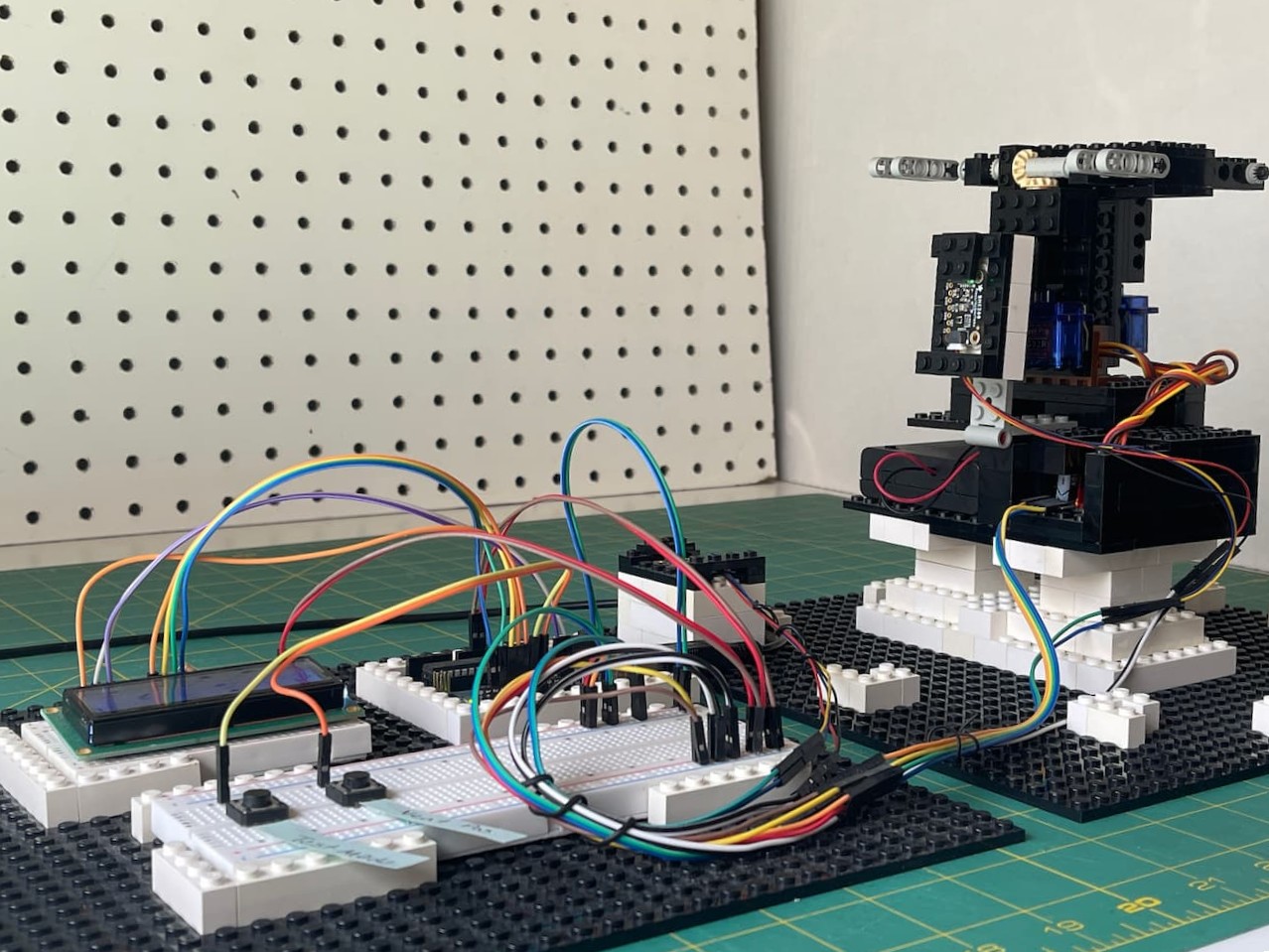

The project began with a simple sketch of a dome structure with articulated panels. This vision was grounded in research of real-world kinetic buildings and natural systems. The current prototype is a functional, scaled model that proves the core concept. It features a “kinetic skin” of ceramic tiles mounted on a mesh backing. An Arduino microcontroller uses a dual-sensor system to compare internal and external temperatures, actuating the panels via a custom, efficient LEGO Technic mechanism.

– The video demonstrates the core functionality of the temperature-responsive system. A heater is used to raise the internal temperature, triggering the vents to open and release heat. A fan then cools the external sensor, causing the vents to close, successfully proving the dual-sensor logic and mechanical linkage.

– Close-up of the Efficient Mechanical Linkage

Technical Highlights & Learnings

- Iterative Prototyping Process: My key learning was the process of translating a conceptual sketch into a functional, sensor-driven reality through methodical iteration, from a simple light-activated model to a more complex temperature-responsive system.

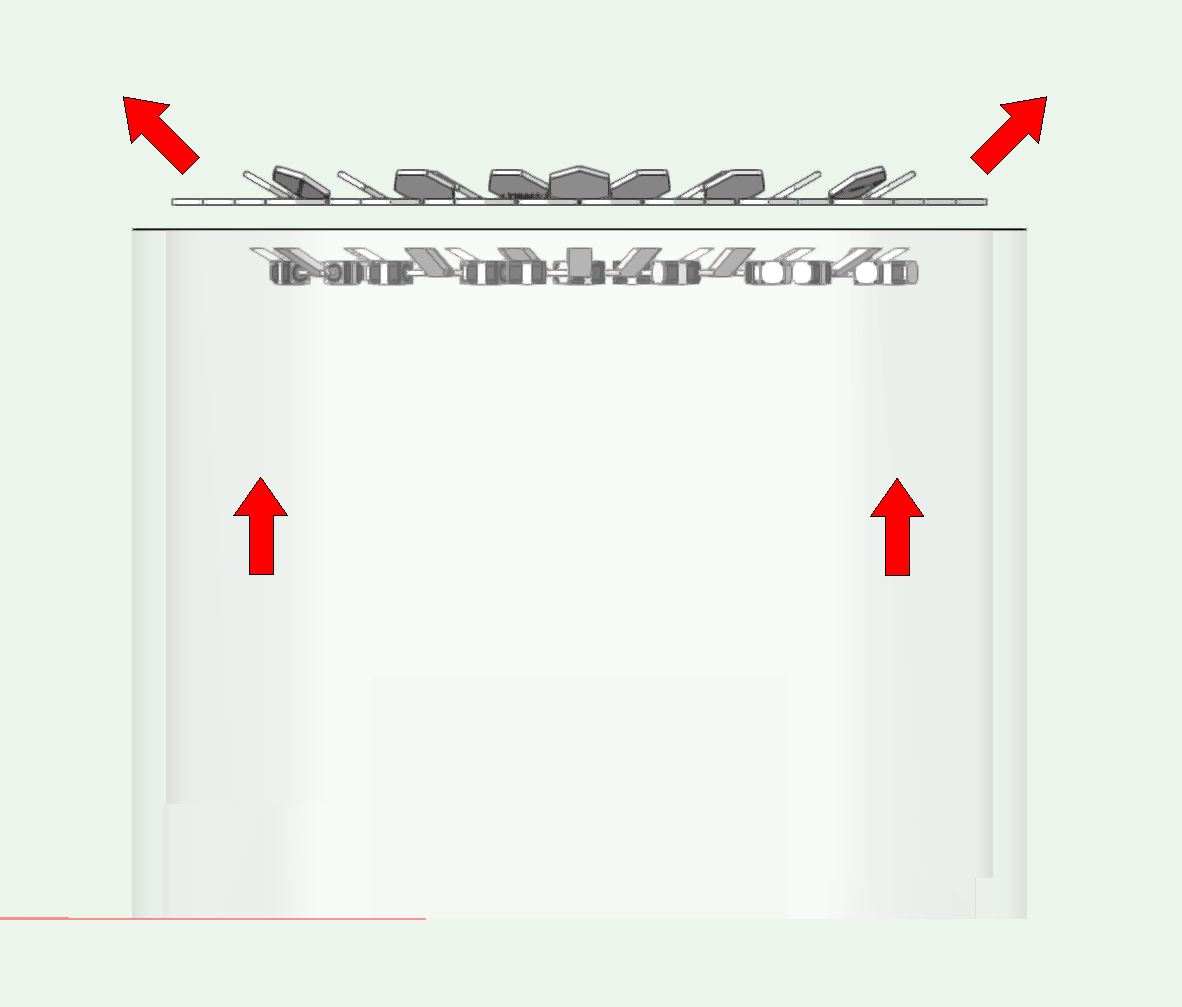

- Efficient Mechanical Linkage: To solve the constraints of a compact form factor, I engineered a ganged system where two servos actuate three panels via a custom LEGO gear-and-lever linkage, reducing mechanical complexity.

- Dual-Sensor Environmental Logic: The system’s intelligence comes from C++ code that makes decisions based on the difference between internal and external environments, ensuring the vents only open when effective.

- Mixed-Material Prototyping: The project demonstrates a resourceful approach by successfully integrating off-the-shelf electronics with custom-fabricated parts (ceramic tiles) and rapid-prototyping components (LEGOs).

- Real-time Feedback: An integrated LCD screen displays live temperature data, with manual override buttons for testing and demonstration.

Tools & Technologies Used

Software: C++ (Arduino IDE), Vectorworks

Hardware: Arduino, SHT40 & BME280 Sensors, Micro Servos, PCA9685, LCD Display, LEGO Technic components, Ceramic Tiles